Welcome to Henan Mine Crane Co.,Ltd.

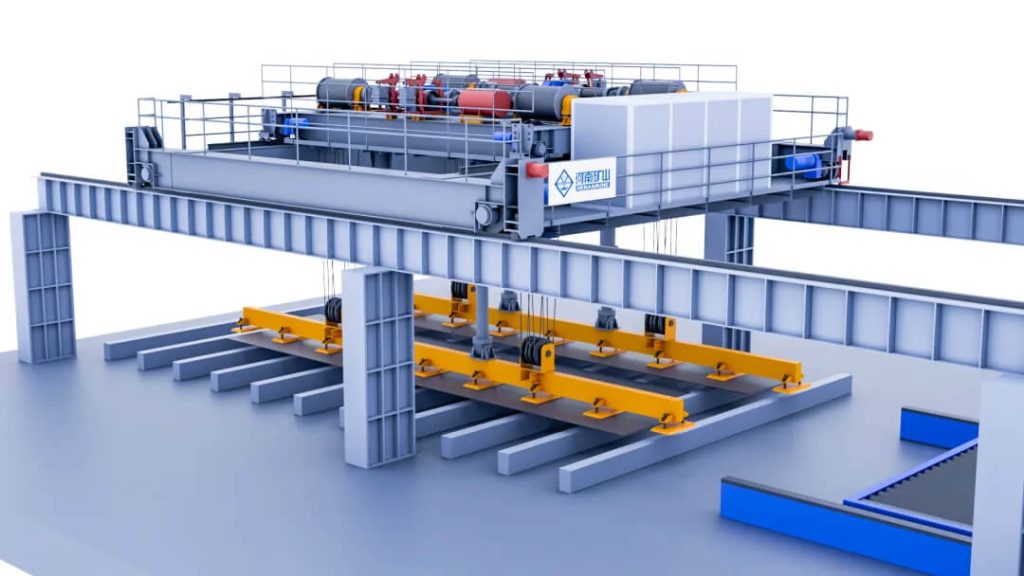

Recently, Henan Mining provided Shandong Iron and Steel Group Rizhao Co., Ltd. with a fully automated steel plate splitting solution for the processing of various high-end medium and heavy plates, such as shipbuilding plates and marine engineering steel. Based on a lifting and material handling system, the solution integrates fully automated operations including laser cutting and splitting of steel plates, surface marking, side stamping, and fixed-length finished product warehousing, achieving an upgrade from traditional material handling to complete production line services.

Fully Automated Closed-Loop Operation Enables Efficient Operations: Deeply integrating automation technology with steel production scenarios, it can complete the precise hoisting, cutting, marking, and loading/unloading of steel plates in a fully automated manner without human intervention; at the same time, it reserves a wireless remote control interface to take into account current needs and subsequent operational adjustments, achieving "one-time investment, long-term adaptability".

It adopts frequency converter + PLC control, and is equipped with intelligent anti-sway function and rigid anti-sway structure of the lifting device to ensure stable lifting; it integrates multiple safety mechanisms such as safety interlock, protection, video monitoring, laser anti-collision and transmission control to achieve comprehensive safety protection.

Whatsapp

Whatsapp