Product Description

The foundry crane is designed to be operated efficiently, uninterruptedly and safely in continuous use.The design conforms to the requirements of international standards.

Because of a higher risk level, special safety features are designed for the foundry crane that transport molten metal. The main hoist mechanism includes four independent rope reevings, double service brakes on primary shafts, and backup brake acting on the rope drum. Rope equalizer beams are provided with a dampening unit to slow down equalizer beam tilting in case of wire rope failure. An upper emergency stop limit switch is also used in the main hoist. In addition to this overload protection, the ‘emergency stop’ system bypassed from PLC, derailment supports, main hoist over speed supervision, and end limit switches are automatically standard features of the equipment.

The foundry crane utilized for medium to heavy fabrication. These overhead cranes are ideally suited to casting factory.The Foundry crane is the main equipment for steel smelting production.

It is used to move steel or iron ladles in steel smelting workshop with high temperature and a lot of dust. Conventional scheme:using the closed cab.

Each organ is H class. And the insulating YZR type motor. working in the highest ambient temperature is 60°C,collocate with the advanced electric the winch is made with the welding's steel board ,the gear box with the detent and the ratchet wheel.

Power: AC 3Ph 380V 50Hz or according to client's requirement.

Control mode: Cabin control/remote control/control panel with pendant line

Parameters

| Mechanism | Item | Unit | Result |

| Item | |||

| Lifting capacity | ton | 5-320 | |

| Lifting height | Main Hook | m | 18-24 |

| Auxiliary Hook | 20-26 | ||

| Span | m | 10.5-31.5 | |

| Working environment temperature | °C | -25~40 | |

| Speed | Main Hook | m/min | 6.8-10.5 |

| Auxiliary Hook | 9.5-14.5 | ||

| Main Trolley | 36-44.6 | ||

| Auxiliary Trolley | 37.5-39 | ||

| trolley | 67-101.8 | ||

| Working system | A7 | ||

| Power source | three-Phase A C 50HZ 380V | ||

Benefits

Best Quality

Fast Delivery

Global Service

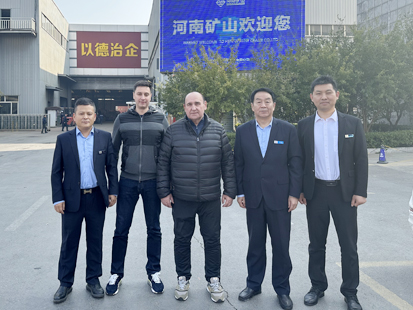

Customer Site

Packing and Shipping

We strictly manage packaging specifications and transportation requirements,Wooden pallets with plastic filmor according to your request.

FAQ

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.